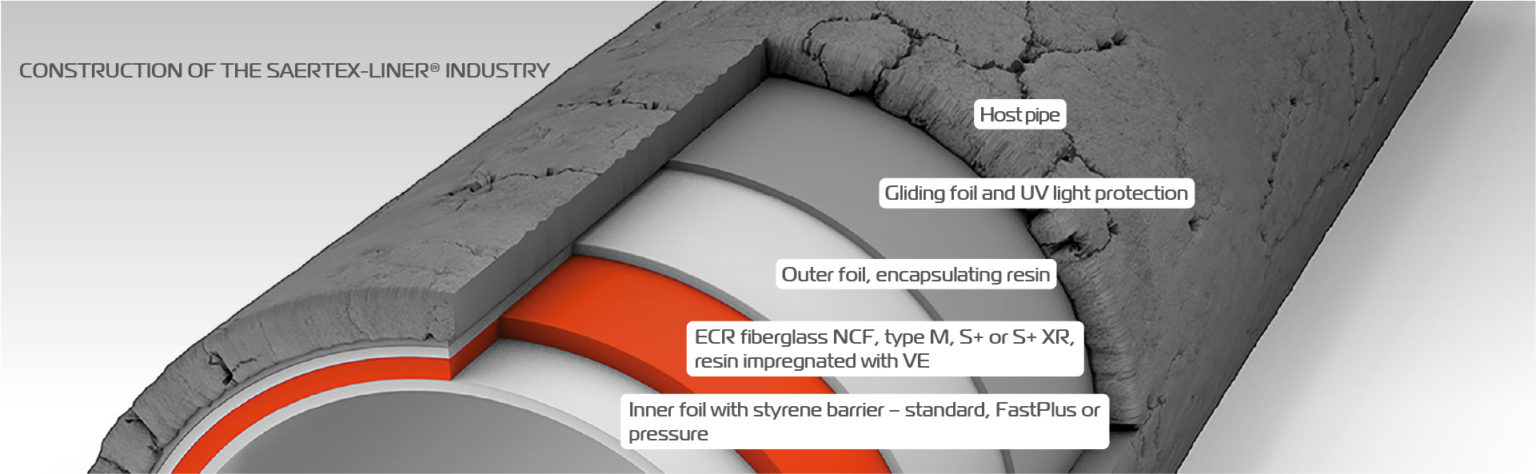

SAERTEX-LINER® INDUSTRY is a combination of vinyl ester (VE) and ECR fiberglass that has been engineered to withstand corrosive chemical environments and higher temperatures. Based on our proven S+ liner design, it is ideal for use in the trenchless rehabilitation of industrial wastewater pipes.

| PRODUCT APPLICATION | SAERTEX-LINER® INDUSTRY |

| Utilization | Corrosive, high-temp wastewater |

| Resin type | VE |

| Temperature and chemical resistance | +++ |

| Styrene-free | no |

| DESIGN | TYPE S+ |

| Host pipe profile | All types |

| Fully structural | ● |

| Diameter [mm] | 150‒1 000 |

| Structural wall thickness [mm] | 3‒10 |

| Max. length [m] | up to 350 [longer on request] |

| FOILS | |

| Outer foils: | |

| – Integrated gliding foil | ● |

| – Resin encapsulating barrier | ● |

| Inner foil with barrier function: | |

| – Standard (temporary) | ● |

| – FastPlus (semi-permanent) | Optional |

| MECHANICAL CHARACTERISTICS | TYPE S+ and TYPE S+ XR |

| Short-term circumferential E modulus [N/mm²] | ≥ 20 500 |

| Long-term circumferential E modulus [N/mm²] | 16 000 |

| Short-term bending E modulus [N/mm²] | ≥ 16 800 |

| Short-term bending stress [N/mm²] | ≥ 270 |

| Long-term bending stress [N/mm²] | 210 |

| Reduction factor (acc. to DIN EN 761): | |

| – 50 years [after 10,000 h] | 1,28 |

| – 100 years [after 20,000 h] | 1,31 |