SAERTEX-LINER® ENVIRONMENT is the styrene-free option in our GRP pipe liner product range. With no styrene emissions, this liner is ideal for the trenchless rehabilitation of wastewater and stormwater pipes in high traffic public spaces and residential areas. It is available in two design options:

| PRODUCT APPLICATION | SAERTEX-LINER® ENVIRONMENT |

| Utilization | Municipal wastewater and stormwater |

| Resin type | SFVE |

| Temperature and chemical resistance | + |

| Styrene-free | yes |

| DESIGN | TYPE S+ | TYPE S+ XR | |

| Host pipe profile | All types | Circular | Circular |

| Application | Gravity | Pressure | Pressure |

| Operating pressure [BAR] | up to 1 | up to 33 | |

| Fully structural* | ● | ● | ● |

| Diameter [mm] | 150‒1 500 | 250‒1 200 | 250‒1 200 |

| Structural wall thickness [mm] | 3‒12 | 4‒12 | 4,3‒12,3 |

| Max. length [m] | up to 350 [longer on request] | ||

| FOILS | |||

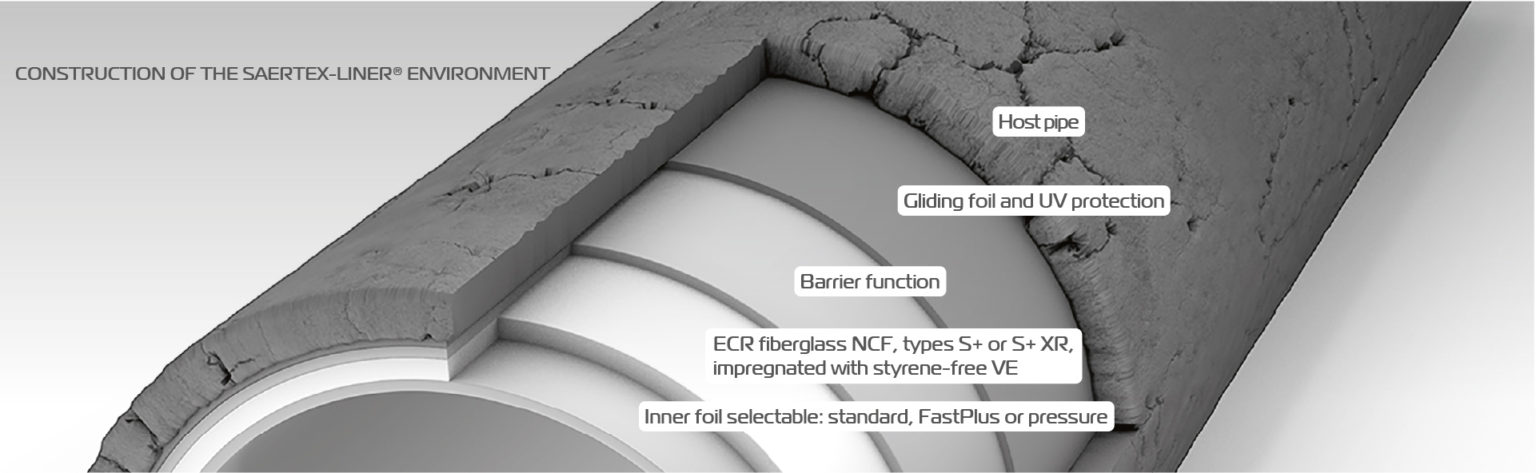

| Outer foils: | |||

| – Integrated gliding foil for ease of installation, UV light protection | ● | ● | ● |

| – Resin encapsulating barrier | ● | ● | ● |

| Inner foil with barrier function: | |||

| – Standard (temporary) | ● | ||

| – FastPlus (semi-permanent)** | Optional | ||

| – Pressure (permanent) | ● | ● | |

| MECHANICAL CHARACTERISTICS*** | TYPE S+ | TYPE S+ XR | |

| Short-term circumferential E modulus [N/mm²] | ≥ 12 950 | ≥ 20 500 | |

| Long-term circumferential E modulus [N/mm²] | 9 450 | 16 000 | |

| Short-term bending E modulus [N/mm²] | ≥ 15 000 | ≥ 16 800 | |

| Short-term bending stress [N/mm²] | ≥ 230 | ≥ 270 | |

| Long-term bending stress [N/mm²] | 165 | 210 | |

| Reduction factor (acc. to DIN EN 761): | 1,37 | 1,28 | |